RodlerBead provides a simply installed properly sized sealant channel for windows, doors and many other penetrations through stucco/plaster building siding.

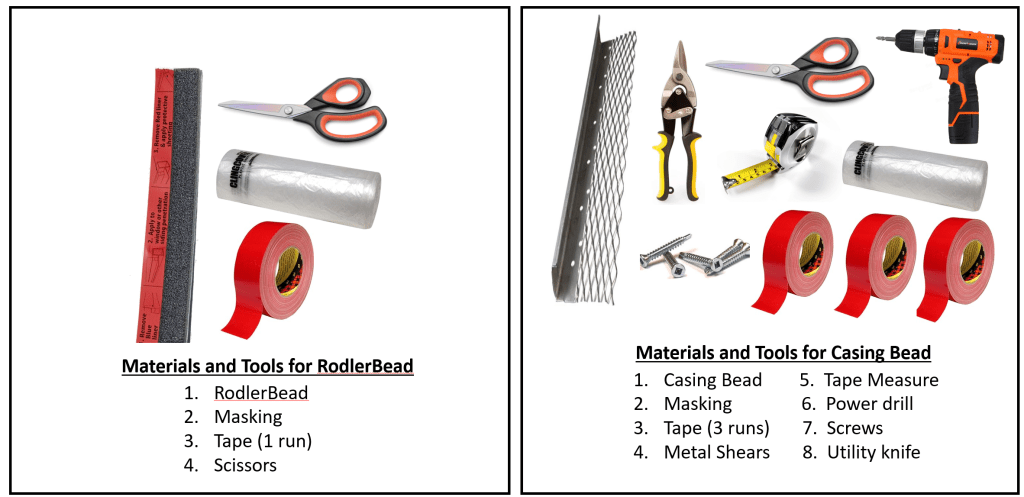

All together, our mock up, done by a very experienced professional installer whom we met on the 1st day of of the mock up test, timed the RodlerBead system at just over 9 minutes faster than the Standard Casing System on this a small window. Times will, of course, vary a lot but there is no question that RodlerBead provides a proper sealant bead channel with less effort, less materials and in less time.

A better Way to create that flexible seal.

RodlerBead is a construction product which reduces the probability of water intrusion and possibility of stucco gapping and or cracking around windows, and other building envelope penetrations.

RodlerBead is an inexpensive multifunction device that is simple to use and has a high cost-to-benefit ratio. It is less expensive and less time consuming: 70% less by our calculation (see the comparison video above).

RodlerBead fulfills the Building Code requirement and window manufacturers’ instructions that stucco be separated from windows and other materials – at a fraction of the cost of the current industry standard.

Product

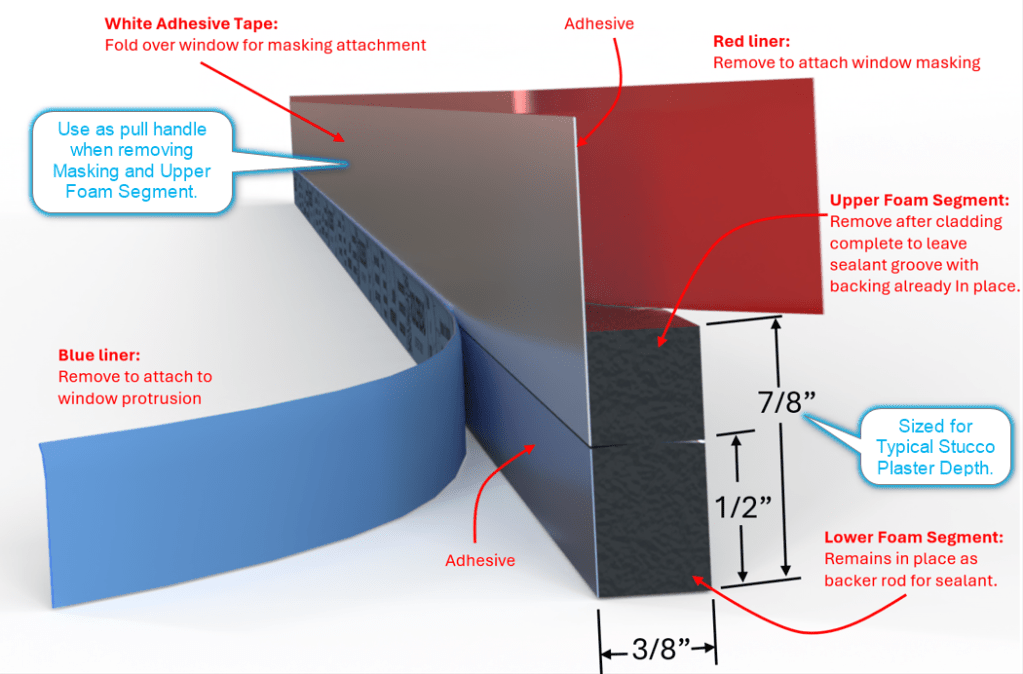

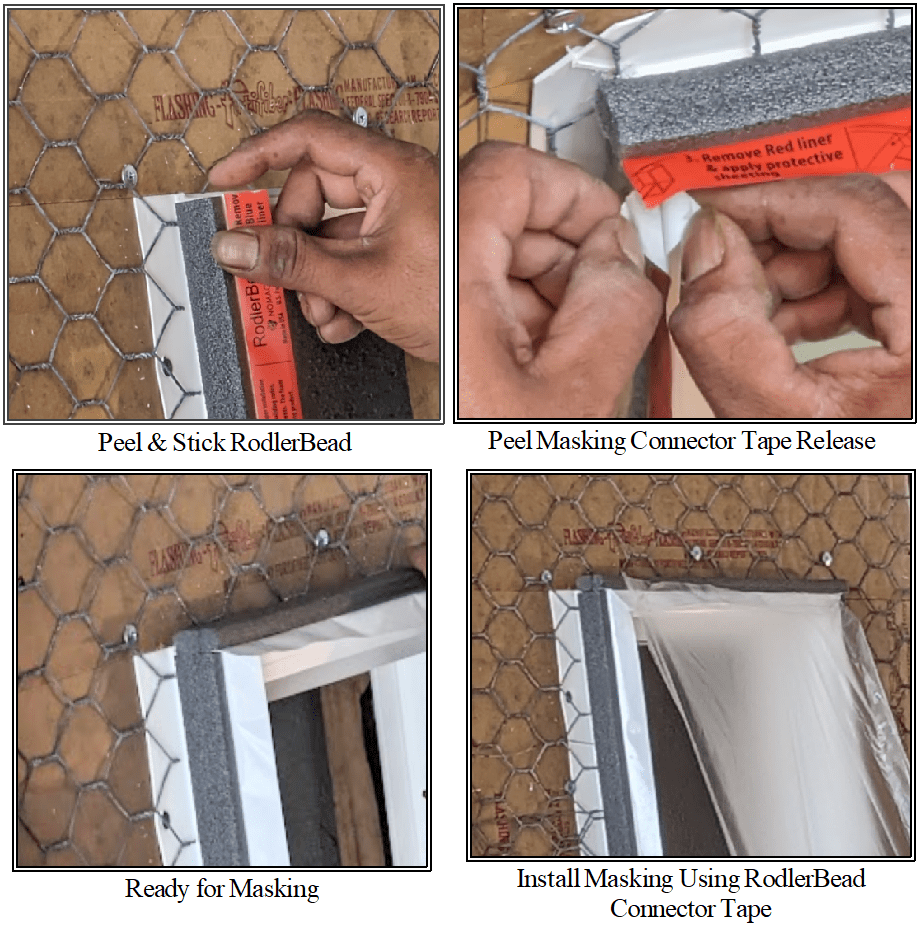

RodlerBead combines the functions of building element spacer, surface finishing screed, masking attachment tape, sealant groove creation, and sealant groove backing material into a single peel and stick strip for simplified sealing of building cladding joints.

RodlerBead is applied with adhesive to the perimeter of the window or other penetration’s, after they are installed and flashed at the sub-siding level, to the building, and before the stucco, or other siding is installed. The RodlerBead will act as a screed during stucco installation, providing a uniform stucco edge against the window, at ⅞” deep.

After the siding is installed, the exterior portion of the RodlerBead is easily removed due to an integral separation slit, leaving a clean and consistent ⅜” wide and deep void to be filled with an appropriate sealant. The sealant bead and remaining portion of RodlerBead form the required separation with ideal dimensions, as prescribed by most construction sealant manufacturers.

The result is a flexible sealant joint between the window and the stucco or siding. This is highly desirable as various materials and stucco (or other sidings) expand and contract at different rates, resulting in water intrusion opportunities between them and the stucco, the most common avenue through which window leaks occur. Additionally, the flexibility of the sealant bead allows the window to expand and contract without causing stucco cracking or gapping, commonly observed at the corners or around the perimeter. RodlerBead may be utilized at nearly any penetration in the building envelope.

Additionally, RodlerBead reduces opportunities for air infiltration. Wind blown moisture is a factor in building leaks – if there are no cracks or gaps in those places we most often see them wind blown rain will have less opportunity to get under the building claddings.

Competition

The conventional code compliant method requires more material and labor than RodlerBead. The conventional method requires a casing bead be applied around the perimeter of the window, masking tape applied to the window and backer rod installed. RodlerBead replaces all of those steps. RodlerBead is less expensive and is easier and faster to install, a two fold cost savings of material and labor.

Leadership Team

The products inventor was Micah Rodler. Micah was a forensic construction consultant who designed complex waterproofing systems utilizing hands on experience and technical training in building science. Micah worked for 11 years for Myles F. Corcoran Construction Consultations Inc. (MFCCC), the premier forensic construction consultants in the Monterey Bay Region and beyond.

Before working at MFCCC Micah was a skilled General Contractor. Micah was a builder who knew his trade. At MFCCC Micah, working with a highly skilled team, studied a wide variety of failed building systems, very often water damaged, and designed proper corrections for them, as well as designing water intrusion prevention systems for new structures during their planning. Micah often did quality control and of the work at both repair and new projects. Micah worked with owners, builders, tradesfolks, engineers, architects and many consultant. Micah’s invention “RodlerBead” is the result of a great deal of practical knowledge.

Sadly Micah passed away several years ago. He was a talented family loving man with a young family. He left the world many good things including the very best way we have seen to create a professional seal on the outside of buildings.

Cora Rodler, Micah’s wife, is the principle owner of RodlerBead. Cora takes part in all board decisions with a founders authority.

Sean Tuttman was a close friend of Micha’s who, upon our losing Micah, determined to apply his considerable business skill towards bringing RodlerBead to market. Sean is skillfully leading RodlerBead into the market.

Jim Starr is VP of Engineering, and Founder of Tautex, LLC and had an agreement with Micah to develop the original prototype of the product. Tautex specializes in intellectual property development and commercialization. Jim provided technical writing for the Patent Application and developed the 1st tooling necessary for automated production. Jim is a principle on the board and contributes his many industry skills as well as the further development of the RodlerBead fabrication machine.

Myles F. Corcoran is a retired Construction Consultant who founded and, for 31 years, operated Myles F. Corcoran Construction Consultations Inc.. Myles led a high quality team specializing in forensic investigations of a wide variety of types of damaged buildings and developing high quality designs of water resistance and water stopping systems of all kinds either to repair those damaged buildings or in the planning stages for new buildings. Myles oversaw construction projects, in a variety of ways from the time he was made a lead for a general contractor in 1983 until he retired in 2021.

Status

United States Patent #9,428,917 (Issued)

If you are an owner who wants the best systems on your upcoming construction project, a construction industry professional, an architect or exterior envelope consultant we believe you will want to look into

Thank you for your consideration.

Sean Tuttman – seantuttman@gmail.com – 415.577.3674

Updated 9/15/24 MFC

ean, Let me know if you see this comment.

Myles 9/17/24

LikeLike